- Main

- Chiller Efficiency

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

CTI and ASHRAE offer crucial guidance on cooling tower mechanics selection. CTI sets standards for design, operation, and maintenance, covering fan drives, motors, fill media, and water distribution systems. ASHRAE, a HVAC&R authority, provides complementary recommendations for mechanical components, energy efficiency, water treatment, and environmental concerns. Both organizations ensure the efficiency, reliability, and safety of cooling towers across diverse applications. Following their guidance is essential for optimal performance and sustainability.

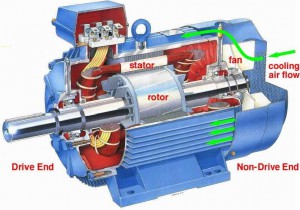

The motor: we will chose a motor based on client’s specification

and power rating. Insulation will be a minimum of IP 55, the enclosure F5 with enclosed ball bearings and a service factor of > 1.12. For direct drive fans, the motor will be installed on a rigid motor support. If driven by a V-belt reducer, the complete drive set is installed on a rigid motor support with V-belt spanner slide.

V-Belt drives < 37 kW / 50 HP: The fan shaft drive is a multi-groove, solid back V-belt with a key lock designed for 1.5 service factor of the motor power. The pulleys are made of industrial grade casted iron. The belt material is neoprene reinforced with polyester cord, specially made for cooling tower conditions. A hinged protective cover in FRP protects the drive from atmospheric impact and indemnifies a safe environment while inspecting the running tower. Belt adjustments are done by sliding the motor frame till the right tension is reached. All drive equipment is manufactured in casted steel and protected with epoxy coating, at least 250 μm.

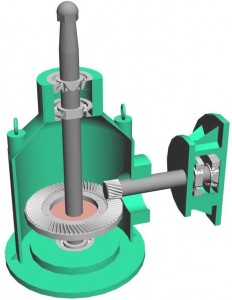

Compact Geared drives <55 kW /40 HP: The shafts are of chromated carbon steel for corrosion protection. The bearings in the fan shaft assembly are of the heavy duty self aligning ball type. The crown wheels are asynchronous in shape and run in an oil bath for the quietest operation and bearing lubrication will never be required. Bearings are designed for a minimum life time of 50.000 hours. All drive equipment is manufactured in casted steel and protected with an epoxy coating of at least 250 μm.

Streamline WB-series.

Monitor your Gear Drives with GEARGUARD

Standard geared drives with shaft 37 to 160 kW 200 HP: The shafts are of chromated carbon steel with for corrosion protection. The bearings in the fan shaft assembly are of the heavy duty self aligning ball type. The crown wheels are asynchronous in shape and run in an oil bath for the quietest operation and bearing lubrication will never be required. Bearings are designed for a minimum life time of 50.000 hours. All drive equipment is manufactured in casted steel and protected with epoxy coating, at least 250 μm. The shaft will either be in carbon steel or composite FRP with SST 316 hardware.

Streamline WB-series.

Monitor your Gear Drives with GEARGUARD

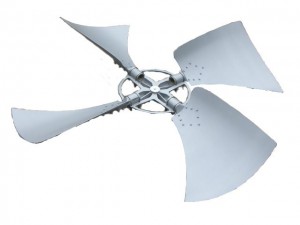

Our highly efficient axial propeller fan will be capable of heavy duty and statically balanced. The fans are an industrial type Class -A- brand to ensure capacity. The fans are manufactured of rolled plate aluminum and a casted aluminum hub. The aluminum hub has a key lock or taper-lock for easy repairs and so each fan blade can be individually adjusted. The fan will be installed in a closely fitted cone with a venturi air inlet for maximum fan efficiency. If required, the fan cone shall be covered with a heavy gauge steel wire fan guard to improve safety.

The fan shaft is chromated carbon steel for corrosion protection. The bearings in the fan shaft assembly are of the heavy duty self aligning ball type. Bearing lubrication shall be not required. Bearings are designed for a minimum life time of 50.000 hours.